Ever wondered how your refrigerator magnets stick so effortlessly, or how scientists detect hidden treasures beneath the Earth’s surface? The magic behind these phenomena lies in magnetization. In the simplest terms, magnetization is the process by which a material becomes magnetized, meaning it develops a magnetic field. This fascinating process occurs when the magnetic moments of electrons within a material align in a coordinated manner, resulting in a noticeable magnetic effect. Whether it’s the tiny compass needle pointing north or the colossal magnets used in industrial applications, magnetization plays a pivotal role in our daily lives and various technological advancements.

Understanding the magnetization method is crucial for anyone interested in the fields of physics, engineering, geology, and even medicine. This method encompasses the techniques and processes used to induce magnetization in materials, enabling a wide array of applications from data storage to medical imaging. By delving into the magnetization method, we unlock the potential to manipulate magnetic properties for innovative solutions and improvements across multiple industries.

What is Magnetization Method?

Alright, let’s dive deeper into the fascinating world of magnetization. You might be thinking, “Isn’t magnetization just about magnets sticking to your fridge?” Well, there’s so much more to it! Magnetization is a fundamental physical process that plays a crucial role in various scientific and industrial applications. But what exactly is it?

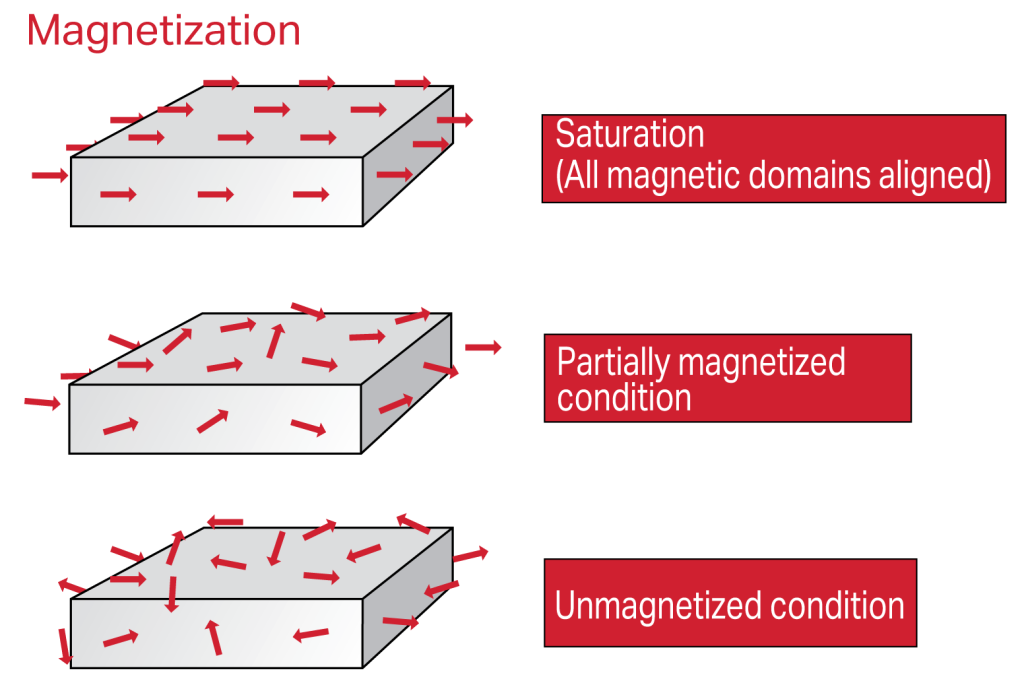

Magnetization refers to the process by which a material becomes magnetized, meaning it acquires a magnetic property. This happens when the magnetic moments of the electrons within a material align in a specific direction, creating a net magnetic field. Imagine tiny magnetic arrows within a material all pointing the same way—that’s magnetization in action!

But why should you care about the magnetization method? Whether you’re a student trying to grasp the basics of physics, an engineer working on cutting-edge technology, or just a curious mind, understanding magnetization opens up a world of possibilities. From powering your electronic devices to enabling groundbreaking medical imaging techniques, magnetization is everywhere!

Magnetization vs. Magnetism

Before we go any further, let’s clear up a common confusion: magnetization vs. magnetism. They sound similar, but they’re not exactly the same thing.

- Magnetization is the process of inducing a magnetic state in a material. Think of it as the action of turning something into a magnet.

- Magnetism, on the other hand, is the phenomenon resulting from magnetization. It’s the observable effect, like the force that makes your fridge magnets stick or the compass needle point north.

To put it simply:

- Magnetization = Action (the process of creating magnetism)

- Magnetism = Result (the magnetic field produced)

Understanding this distinction is key to grasping how the magnetization method works and how it can be applied in various fields.

How Does Magnetization Occur?

Now that we know what magnetization is, let’s explore how it actually happens. Magnetization is a result of the alignment of magnetic moments within a material, but several factors influence this process.

Physical Processes Involved

At the atomic level, magnetization occurs due to the movement and spin of electrons. Each electron generates a tiny magnetic field, and in most materials, these fields cancel each other out because they’re oriented randomly. However, when certain conditions are met, these magnetic moments align in the same direction, leading to magnetization.

There are two primary types of magnetization:

- Permanent Magnetization: In materials like iron, cobalt, and nickel, the alignment of magnetic moments can be sustained even after the external magnetic field is removed. These materials are known as ferromagnetic.

- Temporary Magnetization: Some materials only exhibit magnetization in the presence of an external magnetic field. Once the field is removed, the material loses its magnetization. These are called paramagnetic or diamagnetic materials, depending on their specific properties.

Factors Affecting Magnetization

Several factors influence how magnetization occurs in a material:

- Temperature:

- Curie Temperature: For ferromagnetic materials, there’s a critical temperature called the Curie temperature. Above this temperature, thermal agitation disrupts the alignment of magnetic moments, causing the material to lose its magnetization.

- Material Properties:

- Different materials have varying abilities to become magnetized. Ferromagnetic materials are the most easily magnetized, while paramagnetic and diamagnetic materials require stronger external fields to achieve magnetization.

- External Magnetic Fields:

- The strength and direction of an external magnetic field play a significant role in determining the extent and direction of magnetization. A stronger field can induce greater magnetization.

- Mechanical Stress:

- Applying mechanical stress to certain materials can influence their magnetic properties. For example, hammering a magnet can sometimes realign its magnetic domains, altering its magnetization.

- Time and Frequency of the Applied Field:

- The duration and frequency of the external magnetic field can affect how the magnetic domains within a material align and stabilize.

Understanding these factors is essential for effectively applying the magnetization method in various applications, ensuring that materials behave as desired under different conditions.

The Magnetization Method Explained

What Is the Magnetization Method?

Alright, let’s get to the heart of the matter: What is the magnetization method? At its core, the magnetization method is a systematic approach used to induce magnetization in materials. Think of it as the scientific equivalent of turning a plain sponge into a super-absorbent powerhouse, but instead of water, we’re dealing with magnetic fields.

In more technical terms, the magnetization method involves applying external magnetic fields to a material to align its magnetic domains. This alignment results in the material exhibiting magnetic properties, such as attracting or repelling other magnets. Whether you’re crafting a permanent magnet for your DIY projects or conducting geological surveys to find hidden mineral deposits, the magnetization method is your go-to technique.

But why is this method so widely used? The answer lies in its versatility and effectiveness. From enhancing the performance of electronic devices to enabling precise medical imaging, the magnetization method serves as a foundational tool across various industries. By mastering this method, scientists and engineers can manipulate magnetic properties to achieve desired outcomes, paving the way for innovation and technological advancement.

Historical Background

To truly appreciate the magnetization method, it’s helpful to take a quick trip down memory lane. Magnetization isn’t a modern discovery; humans have been fascinated by magnets for millennia. The earliest records of magnetism date back to ancient Greece around 600 BCE, where the natural magnetite mineral, also known as lodestone, was discovered to attract iron.

Fast forward to the 17th century, and the study of magnetism took a significant leap with the work of William Gilbert. Often hailed as the father of magnetism, Gilbert’s experiments laid the groundwork for understanding Earth’s magnetic field and the behavior of magnetic materials. His seminal work, De Magnete, introduced the concept that Earth itself is a giant magnet, which was a groundbreaking revelation at the time.

The 19th and 20th centuries saw rapid advancements in the magnetization method. The invention of electromagnets by Hans Christian Ørsted and the development of ferromagnetic materials revolutionized industries, enabling the creation of powerful magnets used in motors, generators, and transformers. The discovery of superconductivity further expanded the possibilities, allowing for the generation of incredibly strong and efficient magnetic fields without energy loss.

In recent decades, the magnetization method has evolved with the advent of digital technology and sophisticated magnetic materials. Innovations like magnetic nanoparticles and advanced imaging techniques have opened new frontiers in fields such as medicine, data storage, and environmental science. Today, the magnetization method stands as a testament to human ingenuity, continually adapting and advancing to meet the demands of a rapidly changing world.

How the Magnetization Method Works

Now that we’ve covered the basics and taken a brief historical tour, let’s delve into how the magnetization method actually works. Understanding the mechanics behind this process is crucial for applying it effectively in various applications.

Step-by-Step Process

- Selection of Material:

- The first step involves choosing the right material for magnetization. Ferromagnetic materials like iron, cobalt, and nickel are the most commonly used due to their strong magnetic properties.

- Preparation:

- The selected material is prepared by cleaning and shaping it into the desired form. This could range from simple bars and disks to intricate shapes required for specific applications.

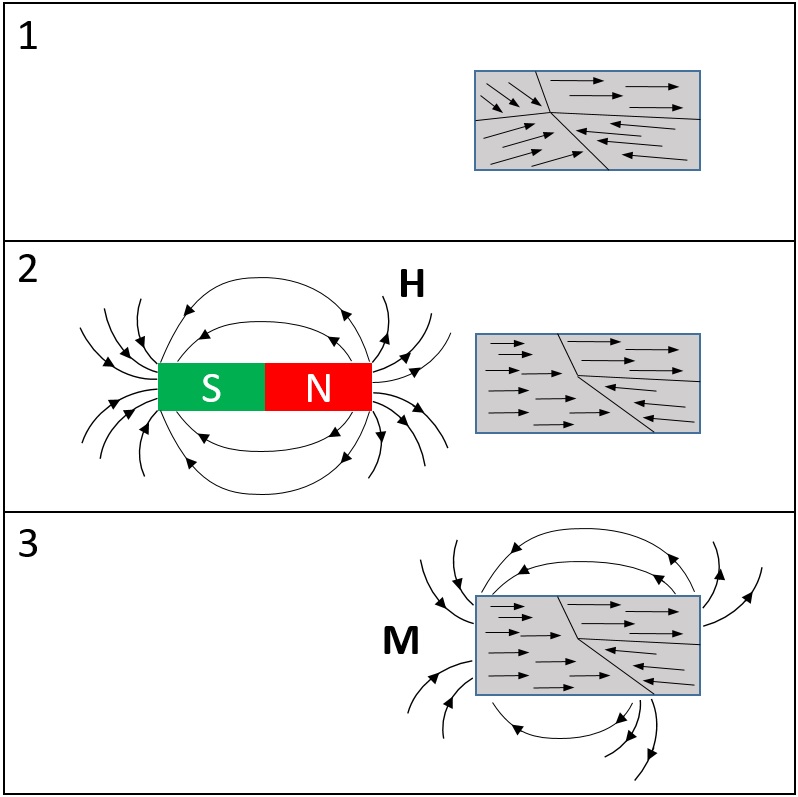

- Application of Magnetic Field:

- An external magnetic field is applied to the material. This can be achieved using permanent magnets, electromagnets, or specialized equipment designed to generate controlled magnetic fields.

- Alignment of Magnetic Domains:

- The applied magnetic field causes the magnetic domains within the material to align in the direction of the field. This alignment is what imparts the material with its magnetic properties.

- Cooling (if necessary):

- In some cases, especially with certain alloys, the material is cooled while maintaining the magnetic field to “lock in” the magnetization.

- Demagnetization (Optional):

- For temporary magnetization, the external field is removed, and the material retains only a portion of its magnetization. For permanent magnetization, the alignment remains stable even after the field is removed.

- Quality Control:

- Finally, the magnetized material undergoes testing to ensure it meets the required magnetic specifications. This step is vital for applications where precision is paramount.

Equipment and Tools Used

The magnetization method relies on a variety of equipment and tools to achieve effective magnetization. Here’s a rundown of the essential gear:

- Electromagnets:

- These are coils of wire that generate a magnetic field when an electric current passes through them. Electromagnets offer the advantage of adjustable field strength, making them ideal for precise magnetization tasks.

- Permanent Magnets:

- Unlike electromagnets, permanent magnets maintain their magnetic field without the need for an external power source. They’re commonly used in applications where a consistent magnetic field is required.

- Magnetic Field Generators:

- These devices create controlled magnetic fields of specific strengths and orientations, essential for uniform magnetization.

- Cooling Systems:

- For certain magnetization processes, especially those involving superconducting materials, cooling systems are necessary to maintain low temperatures and ensure stability.

- Measurement Instruments:

- Tools like Gaussmeters and magnetometers are used to measure the strength and distribution of the magnetic field, ensuring that the magnetization meets the desired specifications.

- Protective Equipment:

- Safety goggles, gloves, and other protective gear are essential when working with strong magnetic fields and electrical equipment to prevent accidents and ensure the safety of personnel.

Types of Magnetization Methods

The magnetization method isn’t a one-size-fits-all approach. Different techniques are employed based on the desired outcome, material properties, and specific applications. Here’s a closer look at the primary types of magnetization methods:

1. Induction Magnetization

Induction magnetization involves inducing a magnetic field in a material without direct contact. This is typically achieved by moving the material through a magnetic field or vice versa. The key advantage of this method is its ability to magnetize objects with complex shapes and sizes uniformly.

Applications:

- Industrial Manufacturing: Used in the production of electric motors and generators to magnetize components efficiently.

- Geological Surveys: Helps in detecting mineral deposits by inducing magnetization in geological samples.

Pros:

- Non-contact method reduces wear and tear on equipment.

- Suitable for large-scale and high-throughput magnetization tasks.

Cons:

- May require precise control of movement and positioning.

- Limited effectiveness on materials with low magnetic permeability.

2. Permanent Magnetization

As the name suggests, permanent magnetization results in a material retaining its magnetization indefinitely. This is typically achieved by exposing the material to a strong, constant magnetic field, causing the magnetic domains to align permanently.

Applications:

- Consumer Electronics: Essential in creating permanent magnets for speakers, headphones, and hard drives.

- Medical Devices: Used in MRI machines and other imaging equipment that rely on stable magnetic fields.

Pros:

- Long-lasting magnetization without the need for continuous external fields.

- High stability and resistance to demagnetization.

Cons:

- Requires strong magnetic fields for effective magnetization.

- Limited to materials that can sustain permanent magnetization, primarily ferromagnetic metals.

3. Electromagnetic Magnetization

Electromagnetic magnetization utilizes electromagnets to induce magnetization in materials. By adjusting the electric current flowing through the electromagnet, the strength and direction of the magnetic field can be precisely controlled.

Applications:

- Data Storage: Fundamental in the operation of hard disk drives and magnetic tape storage.

- Electromagnetic Devices: Used in solenoids, transformers, and inductors to control magnetic fields dynamically.

Pros:

- Highly controllable and adjustable magnetic fields.

- Suitable for applications requiring temporary or variable magnetization.

Cons:

- Requires a continuous power supply to maintain the magnetic field.

- More complex and potentially costly due to the need for electrical components.

Comparison of Magnetization Methods

| Magnetization Method | Advantages | Disadvantages | Common Applications |

|---|---|---|---|

| Induction Magnetization | Non-contact, uniform for complex shapes | Requires precise control, limited on low-permeability materials | Industrial manufacturing, geological surveys |

| Permanent Magnetization | Long-lasting, stable | Requires strong fields, limited material types | Consumer electronics, medical devices |

| Electromagnetic Magnetization | Highly controllable, adjustable | Needs continuous power, more complex | Data storage, electromagnetic devices |

This table highlights the key differences between the three primary magnetization methods, helping you choose the right approach based on your specific needs and constraints.

Applications of the Magnetization Method

Now that we’ve unpacked the magnetization method and understood its various types, it’s time to explore where and how this fascinating technique is applied across different fields. From unearthing hidden treasures beneath the Earth’s surface to revolutionizing medical diagnostics, the magnetization method plays a pivotal role in numerous industries. Let’s dive into some of the most prominent applications of the magnetization method.

In Geology and Earth Sciences

Magnetic Surveying

Imagine being able to peer beneath the Earth’s crust without digging a single hole. Sounds like something out of a sci-fi movie, right? Well, thanks to the magnetization method, geologists can conduct magnetic surveys to explore geological structures hidden beneath the surface.

How It Works: Magnetic surveying involves measuring variations in the Earth’s magnetic field caused by the presence of magnetic minerals in the subsurface. By deploying magnetometers—devices that detect magnetic fields—geologists can map out features like fault lines, volcanic structures, and sedimentary layers.

Applications:

- Mineral Exploration: Identifying areas rich in magnetic minerals such as iron ore.

- Environmental Studies: Assessing soil contamination by detecting magnetic pollutants.

- Archaeology: Locating buried artifacts and structures without intrusive digging.

Case Study: In the early 2000s, a mining company used magnetic surveying to locate a significant iron ore deposit in the Canadian Shield. By analyzing the magnetic anomalies, they pinpointed a lucrative site, saving millions in exploration costs and reducing environmental impact by minimizing unnecessary drilling.

Mineral Exploration

Speaking of minerals, the magnetization method is a cornerstone in mineral exploration. Mining companies rely on magnetization techniques to locate and evaluate mineral deposits, ensuring efficient and targeted extraction.

How It Works: Different minerals have distinct magnetic properties. By analyzing the magnetic signatures of rock formations, geologists can distinguish between various mineral types and assess their concentration and distribution.

Applications:

- Locating Ore Bodies: Efficiently finding deposits of valuable minerals like gold, copper, and nickel.

- Assessing Ore Quality: Determining the purity and concentration of the target mineral.

- Mapping Geological Structures: Understanding the formation and arrangement of mineral-rich zones.

Facts:

- Approximately 70% of the world’s mineral resources are discovered using geophysical methods, including magnetic surveying.

- The magnetization method can detect mineral deposits at depths of up to 5 kilometers, depending on the equipment used.

In Engineering and Manufacturing

Magnetic Materials Processing

In the world of engineering and manufacturing, the magnetization method is indispensable for processing and enhancing magnetic materials. From creating stronger magnets to improving the performance of electronic components, magnetization techniques are at the heart of material innovation.

How It Works: Magnetic materials are treated using various magnetization methods to align their magnetic domains, enhancing their magnetic properties. This process can involve induction, permanent, or electromagnetic magnetization, depending on the desired outcome.

Applications:

- Electric Motors and Generators: Enhancing the efficiency and power output by optimizing magnetic materials.

- Data Storage Devices: Improving the magnetic properties of hard drives and tapes for better data retention.

- Magnetic Sensors: Creating sensitive and accurate sensors for automotive and aerospace applications.

Example: A leading electric vehicle manufacturer employs the magnetization method to produce high-performance magnets for their motors. By precisely controlling the magnetization process, they achieve greater torque and efficiency, contributing to longer battery life and improved vehicle performance.

Quality Control

Ensuring product integrity is paramount in manufacturing, and the magnetization method plays a crucial role in quality control. By magnetizing materials and analyzing their magnetic properties, manufacturers can detect defects and ensure consistency in their products.

How It Works: Magnetization techniques are used to inspect components for structural integrity. For instance, magnetic particle inspection (MPI) involves magnetizing a material and applying ferrous particles to reveal cracks or flaws.

Applications:

- Aerospace Industry: Inspecting aircraft components for micro-cracks and structural weaknesses.

- Automotive Manufacturing: Ensuring the durability and safety of engine parts and chassis.

- Electronics: Checking the integrity of magnetic components in devices like smartphones and computers.

Benefits:

- Non-Destructive Testing: Detecting defects without damaging the product.

- High Sensitivity: Identifying even the smallest flaws that could lead to product failure.

- Cost-Effective: Reducing the need for expensive and time-consuming inspections.

Common Quality Control Methods Using Magnetization

| Method | Description | Applications |

|---|---|---|

| Magnetic Particle Inspection (MPI) | Uses magnetic fields and particles to detect surface and near-surface defects | Aerospace, Automotive, Manufacturing |

| Eddy Current Testing | Applies alternating magnetic fields to detect surface flaws and material properties | Electronics, Metal Fabrication |

| Magnetic Flux Leakage (MFL) | Detects corrosion and pitting in pipelines by measuring leakage fields | Oil and Gas, Pipeline Maintenance |

In Medicine and Healthcare

Magnetic Resonance Imaging (MRI)

When it comes to medical diagnostics, the magnetization method is nothing short of a lifesaver—literally. Magnetic Resonance Imaging (MRI) relies heavily on magnetization techniques to create detailed images of the human body.

How It Works: An MRI machine uses powerful magnets to align the hydrogen atoms in the body. Radio waves then disrupt this alignment, and as the atoms return to their original state, they emit signals that are captured and transformed into detailed images by a computer.

Applications:

- Neurology: Imaging the brain to detect tumors, strokes, and other neurological conditions.

- Orthopedics: Assessing joint injuries, spinal conditions, and musculoskeletal disorders.

- Cardiology: Evaluating heart structures and blood flow for cardiovascular diseases.

Fun Fact: The first MRI machine was developed in the early 1970s, and today, over 40 million MRI scans are performed worldwide each year!

Magnetic Therapy

While not as mainstream as MRI, magnetic therapy is an alternative medicine practice that utilizes the magnetization method for therapeutic benefits. Proponents claim that magnetic fields can help alleviate pain, improve circulation, and enhance overall well-being.

How It Works: Magnetic therapy typically involves wearing magnets on bracelets, insoles, or other wearable devices. The idea is that these magnets influence the body’s own magnetic fields, promoting healing and reducing discomfort.

Applications:

- Pain Relief: Used by individuals to manage chronic pain conditions like arthritis and back pain.

- Improved Circulation: Believed to enhance blood flow and reduce inflammation.

- Stress Reduction: Claimed to have a calming effect on the nervous system.

Skeptical Perspective: It’s worth noting that while many people report positive effects from magnetic therapy, scientific evidence supporting its efficacy is limited. Always consult with a healthcare professional before starting any alternative therapy.

So, if your wrist is feeling a bit “un-magnetized,” maybe it’s time to snap on a magnetic bracelet! (Just don’t expect it to double as a fridge magnet.)

The magnetization method is a versatile tool that transcends various disciplines, offering unique solutions and advancements in each field. Here’s a quick recap of its key applications:

| Field | Application | Benefit |

|---|---|---|

| Geology and Earth Sciences | Magnetic Surveying, Mineral Exploration | Discover hidden structures and valuable minerals efficiently |

| Engineering and Manufacturing | Magnetic Materials Processing, Quality Control | Enhance material properties and ensure product integrity |

| Medicine and Healthcare | MRI, Magnetic Therapy | Provide detailed diagnostics and alternative pain management options |

Key Applications of the Magnetization Method

| Application | Description | Key Benefits |

|---|---|---|

| Magnetic Surveying | Mapping geological structures using magnetic fields | Non-invasive exploration, cost-effective |

| Mineral Exploration | Locating and evaluating mineral deposits | Efficient resource identification |

| Magnetic Materials Processing | Enhancing and optimizing magnetic properties of materials | Improved performance and efficiency |

| Quality Control | Inspecting products for defects using magnetization | Ensures product reliability and safety |

| Magnetic Resonance Imaging (MRI) | Creating detailed internal body images | Advanced medical diagnostics |

| Magnetic Therapy | Using magnets for pain relief and wellness | Alternative pain management |

The magnetization method continues to be an indispensable technique, driving innovation and efficiency across multiple sectors. Whether it’s unearthing Earth’s hidden treasures, ensuring the safety and quality of manufactured goods, or advancing medical technology, the applications of magnetization are as diverse as they are impactful.